Fold-up nature conservation

Innovative noise protection as a vertical compensatory measure

Reference: Joining an 11 m high wall of rammed earth elements, Herzog de Meuron/Martin Rauch

Sustainable noise protection and renaturation promotion

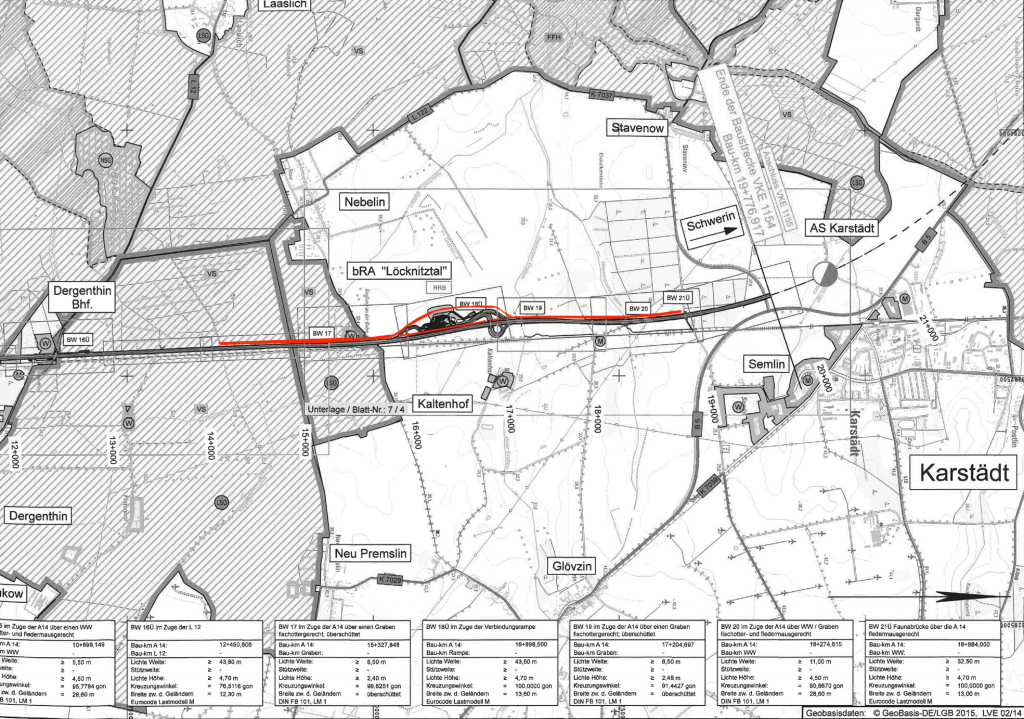

Instead of a conventional solution, such as an earth wall or steel/aluminium/concrete wall, we propose a noise protection prototype in rammed earth or Weller loam construction technique between kilometers 16 to 20 as part of the construction of the A14 south of Karstädt.

Due to its mass and porous surface, clay has an extremely high noise protection factor.

Clay construction is sustainable, uses excavated material and building materials from the immediate surroundings and is also a near-natural building.

Such a noise protection wall uses, innovatively conceived, the Weller loam and rammed loam techniques that were widespread in East Germany until 100 years ago. Aesthetically it blends into the landscape in terms of materiality and colour.

Inhabited cob wall, Foto: Christian Hansel, Lovis Lehmbau

A noise protection wall made of stamped or cob additionally fulfils the function of a vertical compensation measure and thus prevents additional land consumption.

It also provides a refuge for many insect species, including specially protected wild bees.

The technology has already been used for large modern buildings (Ricola, Herzog de Meuron/Martin Rauch; Ozeaneum, Bolthauser; Alnatura headquarters Darmstadt, Martin Rauch, testing in individual cases RZS) and has thus proven its industrial usability. Durability is guaranteed by the special construction technique; at the same time, dismantling is possible with comparatively little effort. A loam wall in Weller or compacted loam construction is practically maintenance-free and causes no further costs.

In its function as noise protection and vertical, ecological compensation measure, the wall in the Prignitz district has the potential to become a European showcase project.

Feasibility study and prototype

The development of a prototype is aimed at machine production and thus low production costs.

In a research project, the statics and construction and the function of a noise barrier made of clay for the promotion of biodiversity, its feedback effects on the region and its energy balance are to be investigated. Workshops to plan details with local people make the wall an identification object of regional solidarity.

Planned route section with envisaged noise protection

Material test in one of the areas affected by noise. Photo: Deven, Alfred-Herrhausen-School, June 2019

Partner

– Lehm Ton Erde Baukunst GmbH, Mag. Martin Rauch (process engineering rammed earth construction)

– Knippers Helbig GmbH, Dr.-Ing. Jan Mittelstädt (construction)

– Bosch & Partner GmbH, Dr. Dieter Günnewig (evaluation as ecological compensation)

– TH Lübeck, Prof. Arch. DPLG CEAA Heiner Lippe (analyses), Prof.Nils Kohlhase (machine engineering)

– Lehmbau Lovis UG, Christian Hansel (cob specialist)

– Institute for Ecology, TU Berlin, M. Sc. Anika Kristin Gathof (specialist for wild bee habitats)

– Zentrum für Peripherie (Centre for Periphery), Ute Reeh (idea development, process and form)

Additional project partners

– BASt, Federal Motor- and Highway Research Institute, Department of Environmental Protection (scientific support)

– Federal Foundation for Build Culture, Chairman Reiner Nagel (building culture aspect)

– Elbe River Landscape Biosphere Reserve, Dr. Heike Ellner (advice and monitoring)

The feasibility study was funded by the Deutsche Bundesstiftung Umwelt (DBU) and the Ministries for the Environment and

the Ministry of the Environment and the Ministry of Economics in Brandenburg.